Dr. Inyang Uwak

Research and Policy Director

On the evening of Thursday, May 16, a 100mph derecho wind storm hit the Houston area, bringing with it rapidly moving thunderstorms that caused widespread power outages, significant property damage, and eight fatalities.

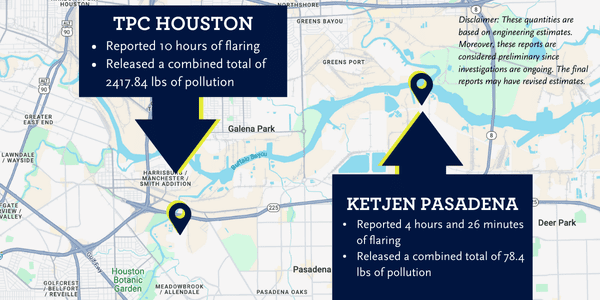

With the widespread power outages came flares from industrial facilities in the area. Below are details from the two facilities that flared, as reported in the Texas Commission on Environmental Quality’s emission inventory.

Disclaimer: These quantities are based on engineering estimates. Moreover, these reports are considered preliminary since investigations are ongoing. The final reports may have revised estimates.

TPC Houston

Time: 10 hours

Emission point: Plant flare

Pollutant and quantity:

- 1,3 Butadiene: 276.51 lbs

- Butanes: 421.54 lbs

- Butenes: 1228.98 lbs

- Carbon Monoxide: 20.24

- Ethylene: 13.76 lbs

- Nitrogen Oxides: 3.92 lbs

- Pentanes: 404.93 lbs

- Propane: 27.48 lbs

- Propylene: 20.07 lbs

- Sulfur Dioxide: 0.41 lbs

2,417.84

Total pounds of pollutants released by TPC Houston

Stated cause: “On 5/16/2024, the Houston Plant experienced a sitewide power loss during an extreme weather event, which resulted in flaring. The root cause investigation (RCI) is ongoing.”

Ketjen Pasadena Plant – Owned by Albemarle Corporation

Time: 4 hours, 26 minutes

Emission point: Specialities Wet Flare

Pollutant and quantity:

- Ethylene: 78.4 lbs

78.4

Total pounds of pollutants released by Ketjen - Pasadena

Stated cause: “Weather conditions due to a thunderstorm caused the loss of pilot lights on the Specialties Wet Flare (EPN: G-D-1) at 6:49 pm on Thursday, 5/16/2024. Once recognized, venting to the flare was to be discontinued. However, some operations were in the middle of venting, leading to emissions of ethylene that were routed to the flare when it was not lit. There were intermittent pilot light outages until 11:14 pm”

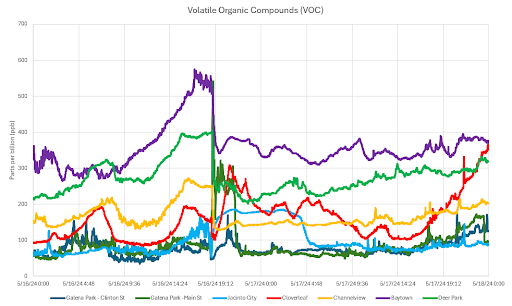

Pollution levels captured by AAH community air monitors

Our community air monitors also captured high concentrations of Nitrogen Dioxide (NO2) and volatile organic compounds (VOCs), congruent with the flared compounds. The highest concentration of NO2 was observed in the Galena Park -Clinton Street monitor.

In Texas, flaring is regulated by both the TCEQ and the Railroad Commission of Texas (RRC) under Statewide Rule 32 (16 Texas Administrative Code §3.32). TCEQ presides over permitting related to refineries and petrochemical facilities, while RRC has authority over the process for pipelines. Under rule 32, facilities can apply for a loophole permit to the RRC to flare legally under certain circumstances. Some of these circumstances include safety flaring or emission events when facilities must rapidly depressurize their systems in emergency situations (e.g., power outages or hurricanes) by burning off excess gas to avoid explosions or fire. However, this can be prevented if these facilities have efficient emergency preparedness, including developing a Risk Management Plan (RMP), weatherizing their facilities, upgrading aging equipment and technology, and improving extreme weather resilience and back-up power sources to prevent flaring in the first place.